Have you ever walked into your kitchen only to be greeted by strange noises from your freezer? While the occasional hum or buzz is usual, persistent or unusual sounds can be concerning.

Understanding the reasons of why is your freezer making weird noises can help you troubleshoot and, if necessary, decide when to call in the professionals.

6 Reasons Why Your Freezer is Making Weird Noises

Here are some common causes of weird freezer noises and how to address them.

- Ice Maker Issues

If your freezer is equipped with an ice maker, it’s often the prime suspect for strange noises. The sound of ice being made, falling into the bin, or the motor running can all create a range of noises.

However, a grinding or mechanical noise could indicate a problem with the ice maker’s motor or gears. To troubleshoot, inspect the ice maker for any visible blockages or damage.

If the problem persists, consider turning off the ice maker to see if the noise stops. If the problem persists, call professionals to get your freezer repaired.

- Defrost Cycle Sounds

Freezers periodically enter a defrost cycle to prevent ice build-up. You might hear popping, hissing, or sizzling sounds during this cycle.

These noises are typically standard and result from the melting ice dripping onto the defrost heater. However, if the sounds are excessively loud or prolonged, they might indicate an issue with the defrost timer or heater.

Checking the defrost components for signs of wear and tear can help identify if a replacement is necessary.

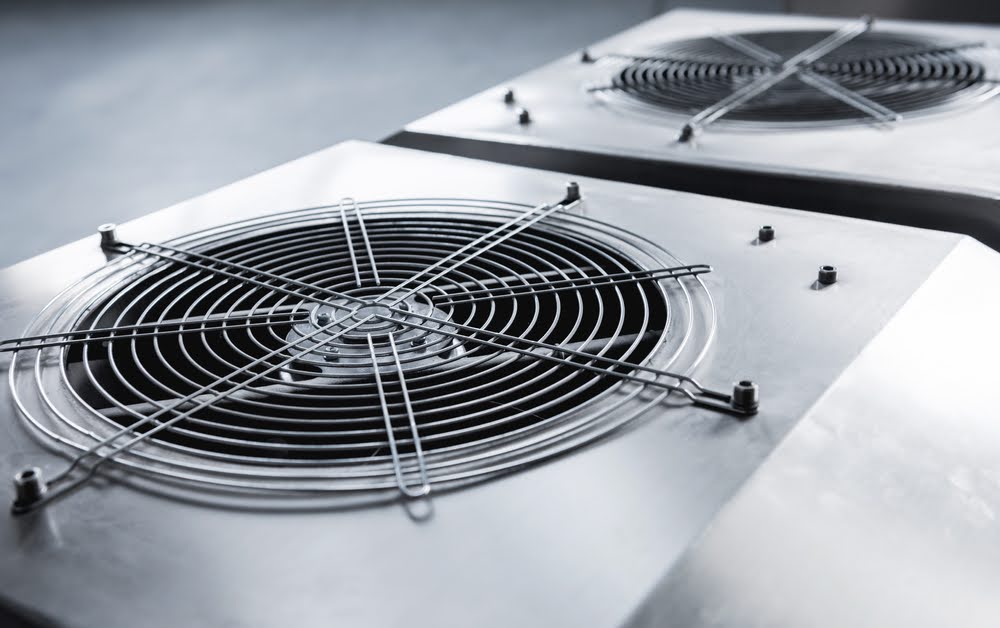

- Fan Problems

Most freezers have at least one fan to circulate cold air. These fans can sometimes become noisy due to dirt build-up, ice accumulation, or mechanical issues.

A high-pitched squeal or a rattling noise often points to a fan problem. Cleaning the fan blades and checking for ice build-up can resolve these noises.

Replacing the fan might be the best solution if the fan appears damaged or worn out.

- Compressor Concerns

The compressor is the heart of your freezer’s cooling system. When running, it’s normal for it to produce a low hum.

However, loud banging, clunking, or knocking noises can indicate a severe issue, such as a failing compressor or loose components. Given the complexity and cost of compressor repairs, it’s usually advisable to consult a professional if you suspect a compressor problem.

- Vibration and Lose Parts

Sometimes, the noise source can be as simple as vibration or loose parts. For example, if your freezer is not level or in contact with cabinets or other appliances, it can create rattling or vibrating noises.

Checking that the freezer is on a stable surface and ensuring enough clearance on all sides can help minimize these sounds. Additionally, inspecting the interior and exterior for any loose screws or panels and tightening them can often silence annoying rattles.

- Expanding and Contracting Materials

As your freezer cools and warms slightly during regular operation, the materials inside can expand and contract, creating clicking or popping sounds. These noises are typically harmless and part of regular operation.

However, if these sounds are unusually loud or frequent, it might be worth investigating to rule out other issues.

Get the Professionals on the Case

While some noises from your freezer are standard, others can indicate underlying problems that need attention. Regular maintenance can prevent many issues.

However, if you’ve tried troubleshooting and the noises persist, it might be time to seek professional help. A-Tech Repair is the expert to call for any weird freezer noises, ensuring your freezer runs smoothly and quietly. Contact us whenever you need assistance with appliances like this!